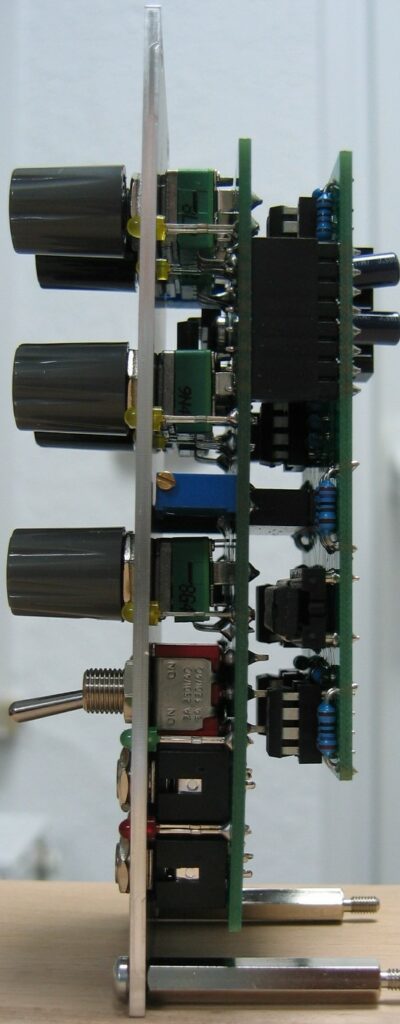

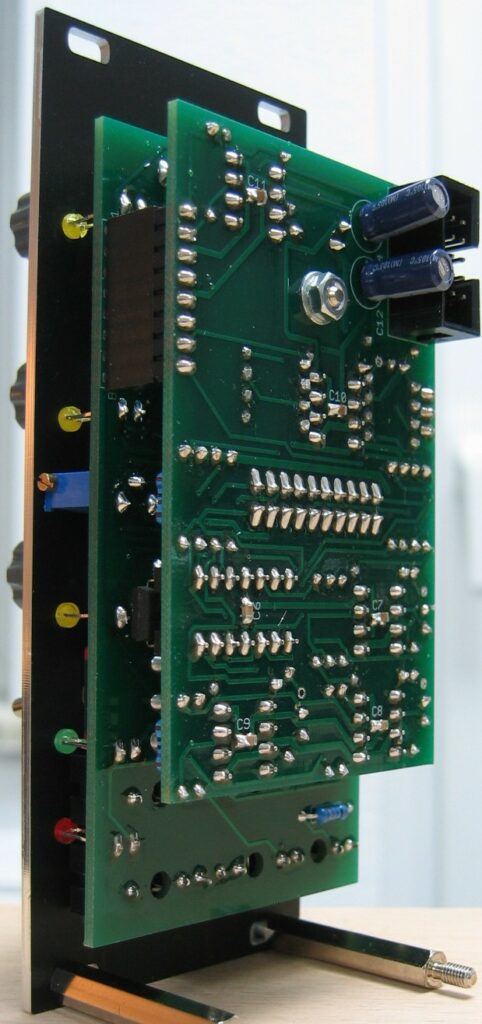

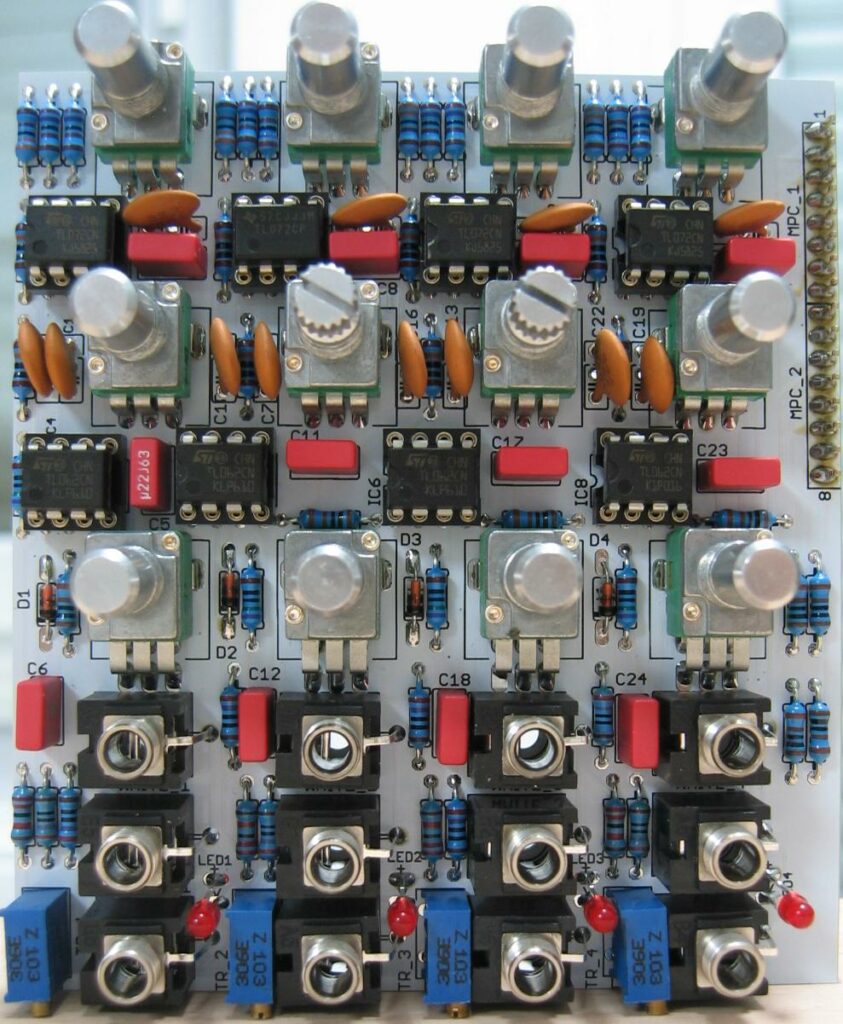

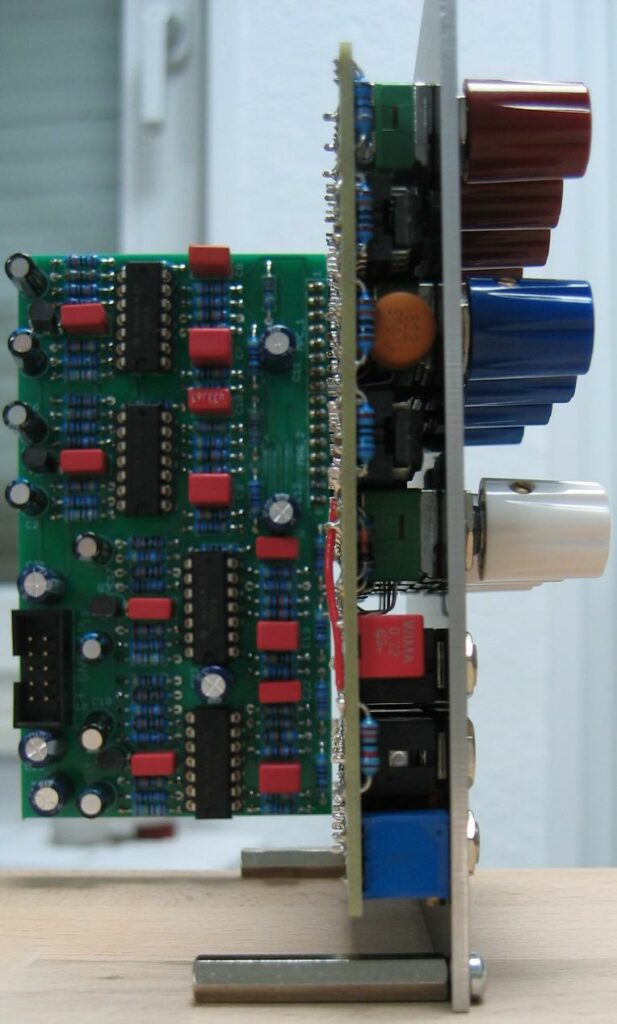

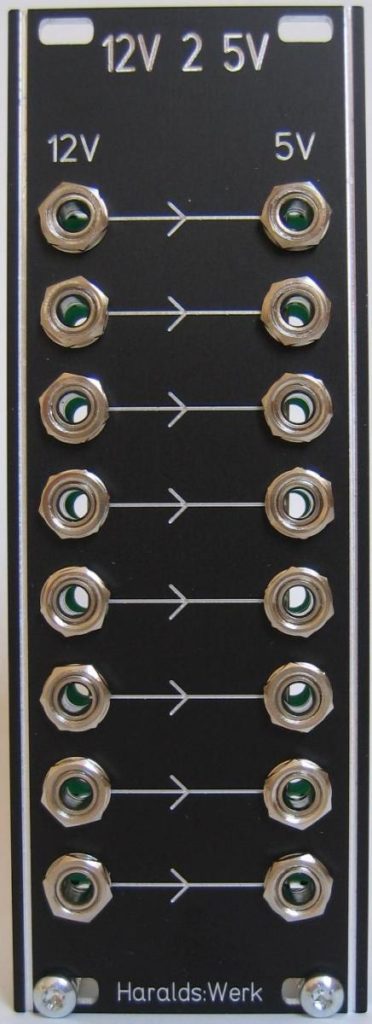

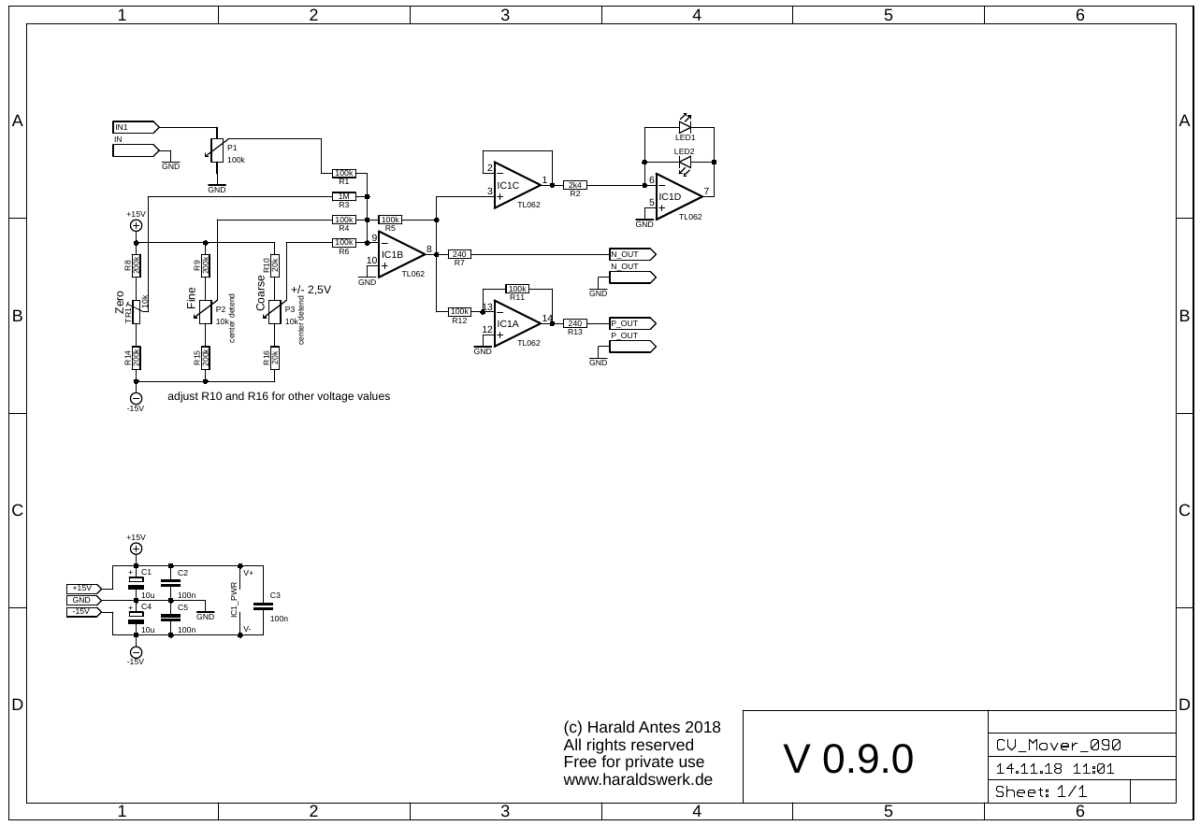

This is an often used utility module. The mixer comes in handy for mixing CV sources. The mixer is DC coupled, so you can use it for DC and AC mixing. The input impedance is constant 1MOhm. The input signals are amplified by a maximum factor of two. It is possible to offset every input with +/- 5V. The offset is signaled with LED’s for every channel and for the summing output. The outputs are normalized, so you can remove selected channels from the output mix. The summed output has a -6dB switchable attenuator. There is an inverted summed output added as well. The added volume indicator us useful for finding the appropriate signal level.

Specs and features

- Three inputs, three outputs

- Inverted and non- inverted summed output

- 2x amplification

- +/- 5V offset for every channel

- -6dB switch

- Volume indicator

- Normalized outputs

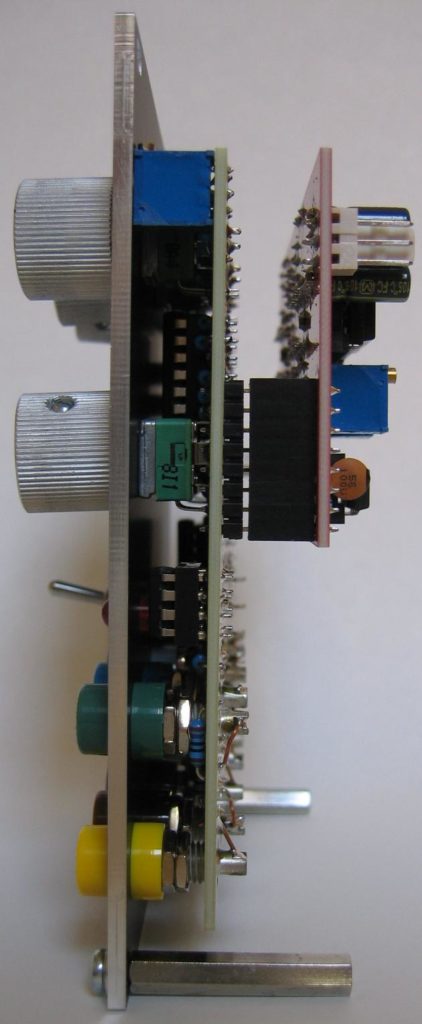

- Runs on +/-12V and +/-15V

- Power consumption below 20mA each rail

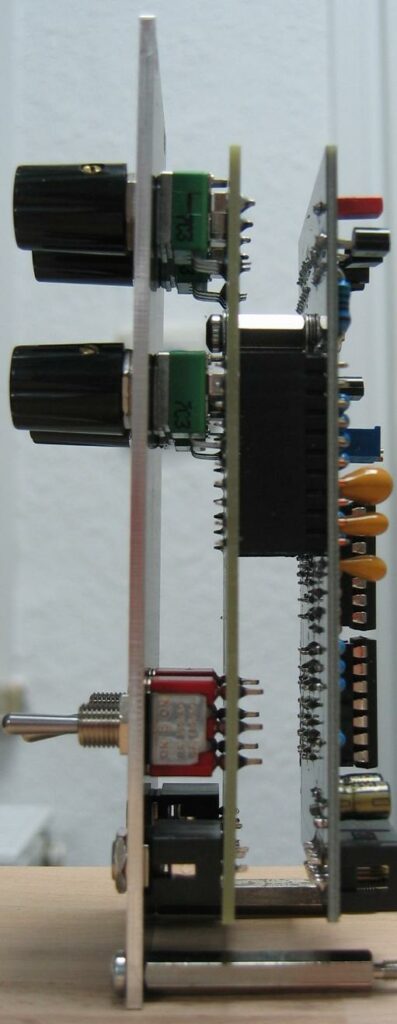

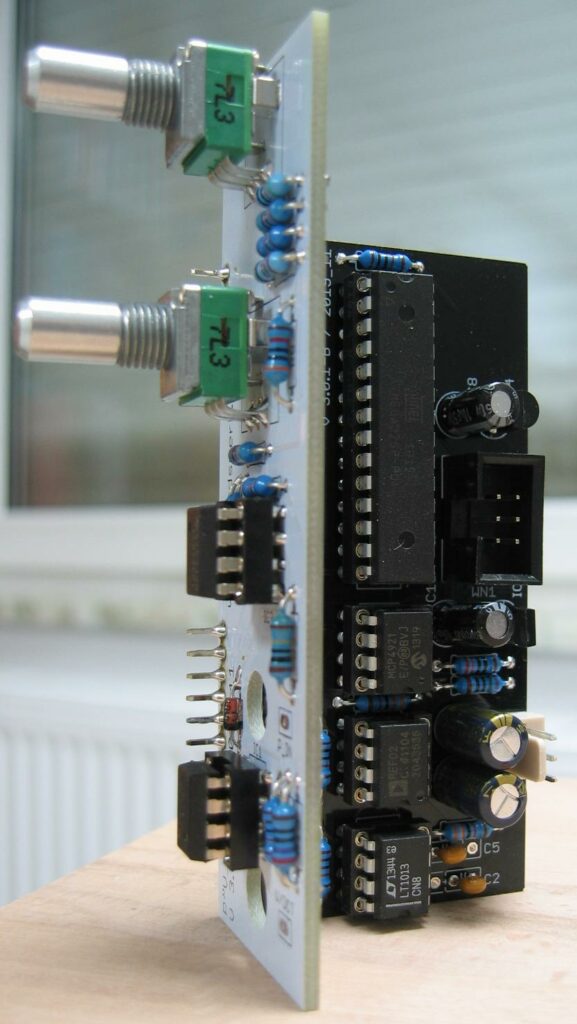

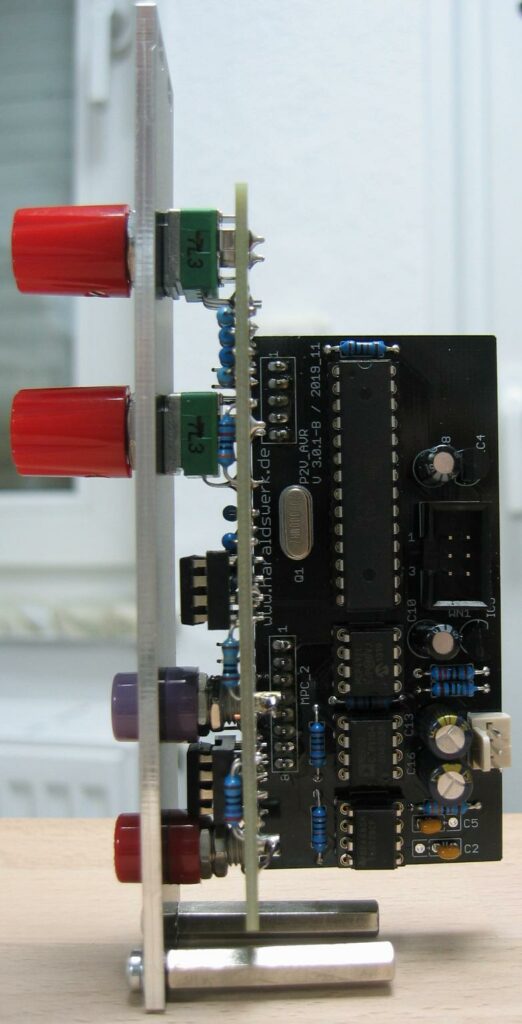

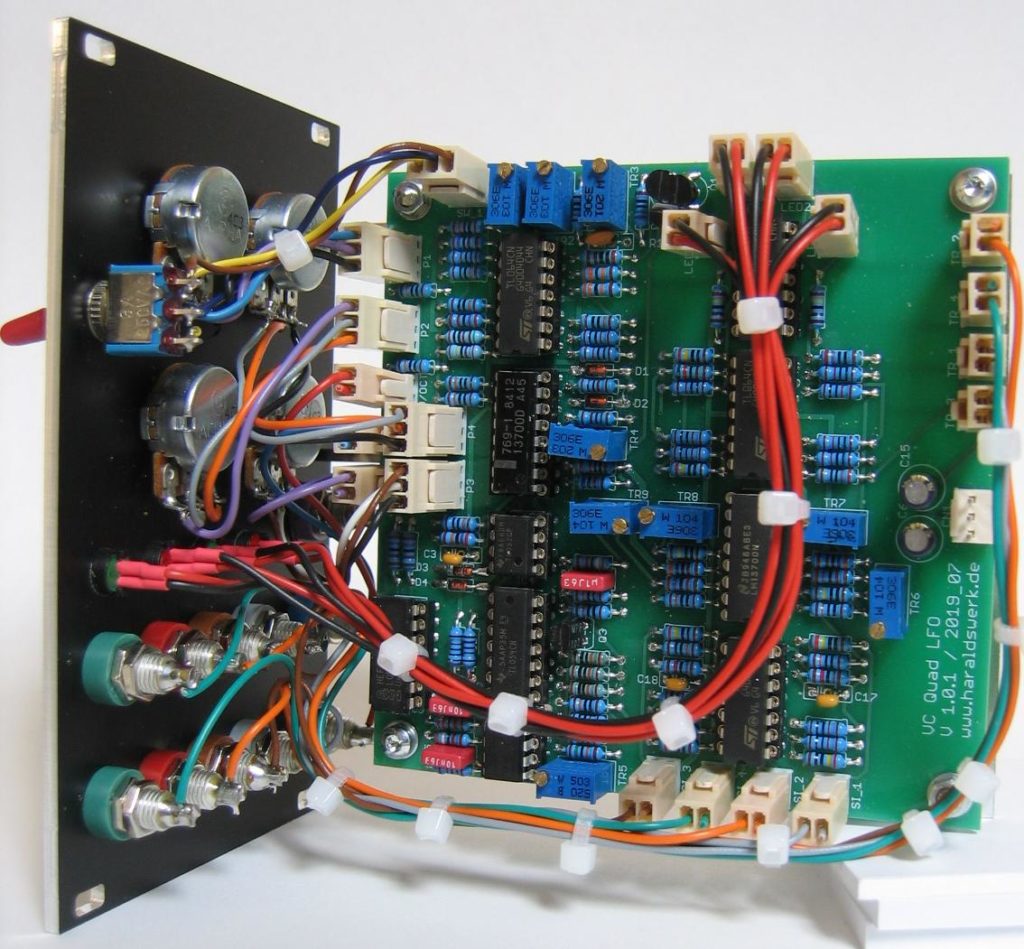

The documentation and the Gerber files for download can be found in my website.

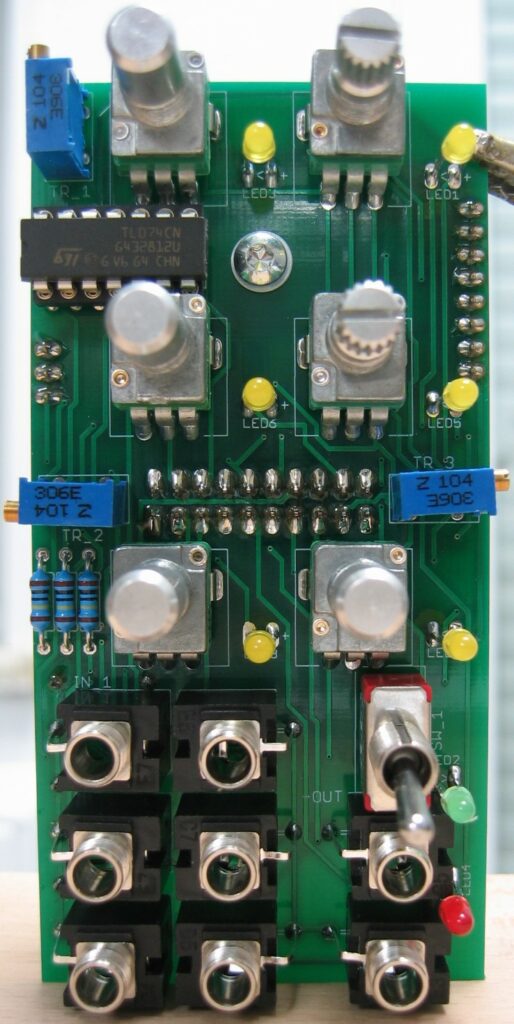

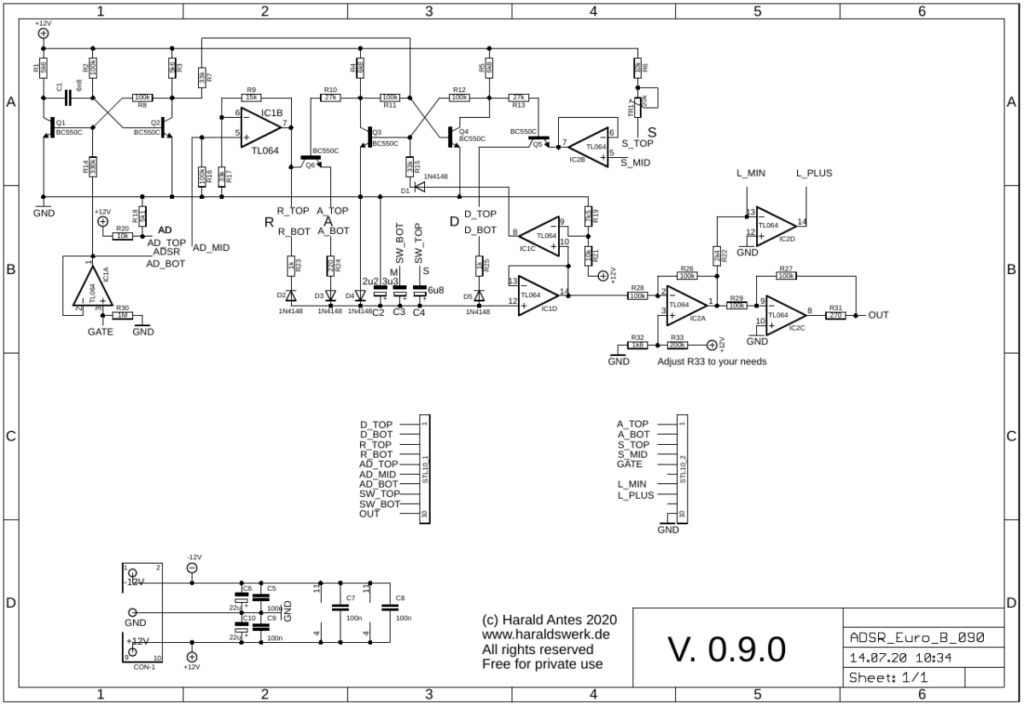

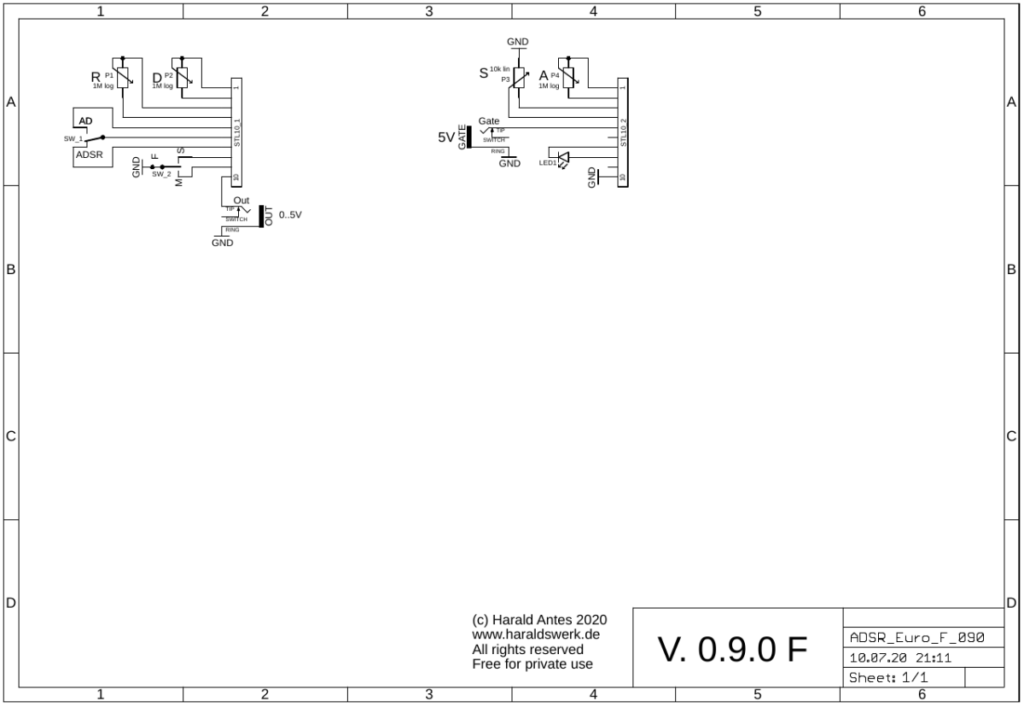

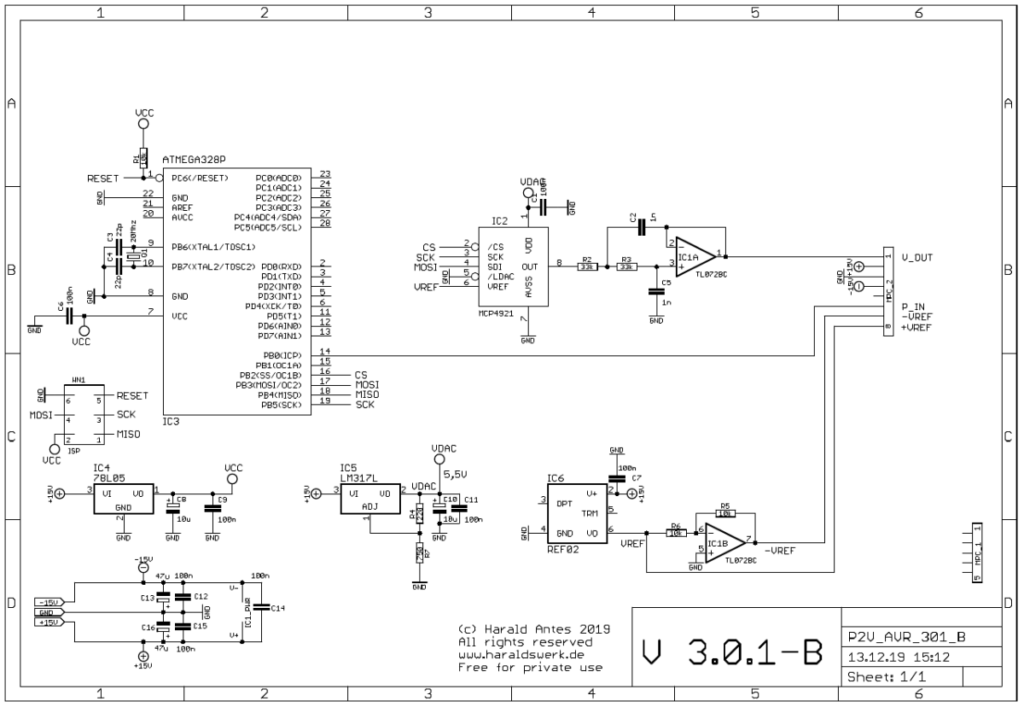

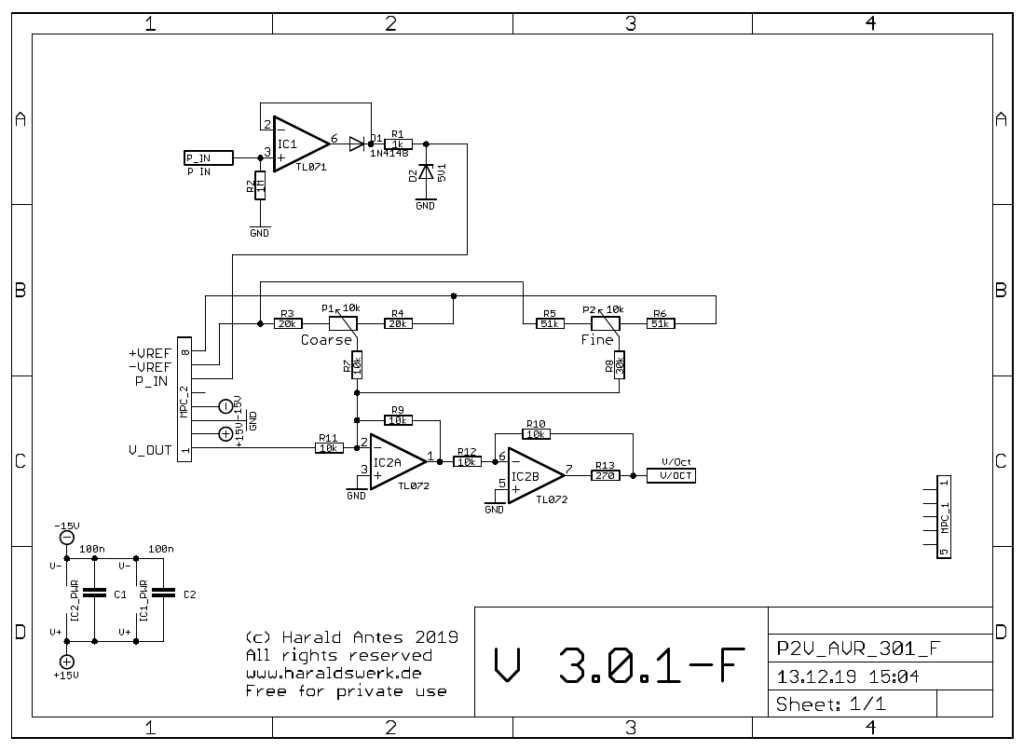

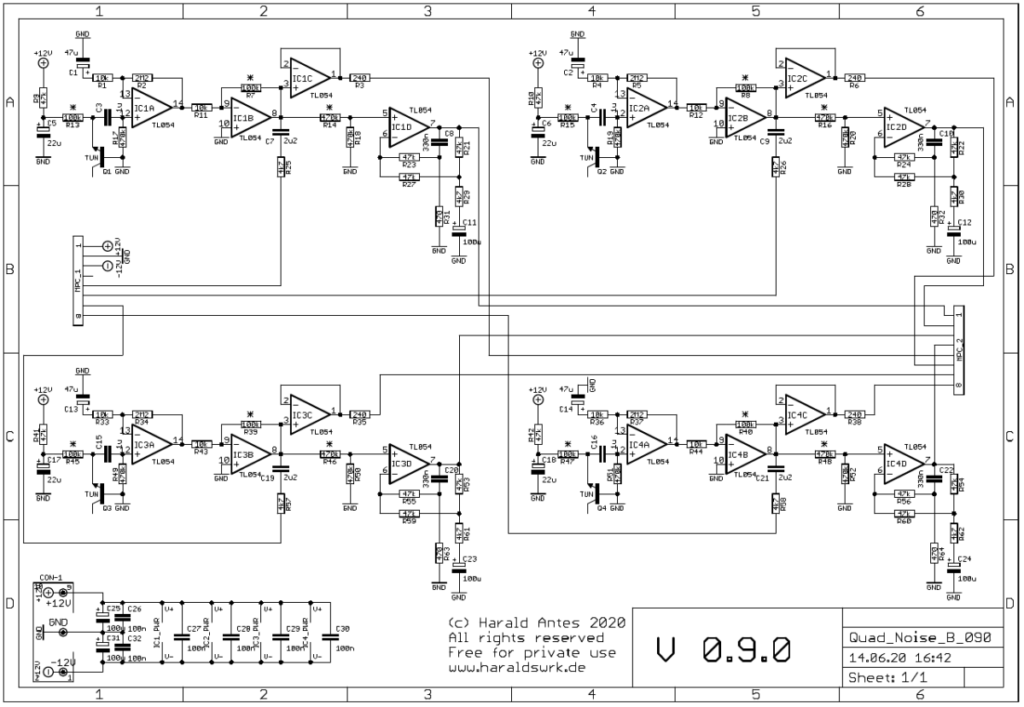

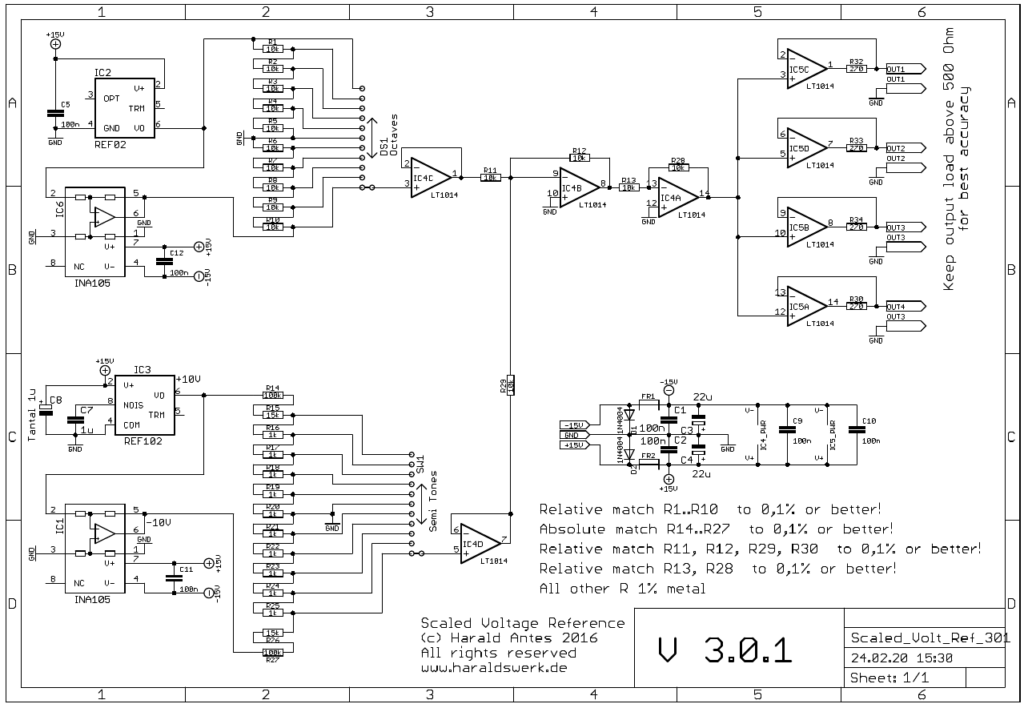

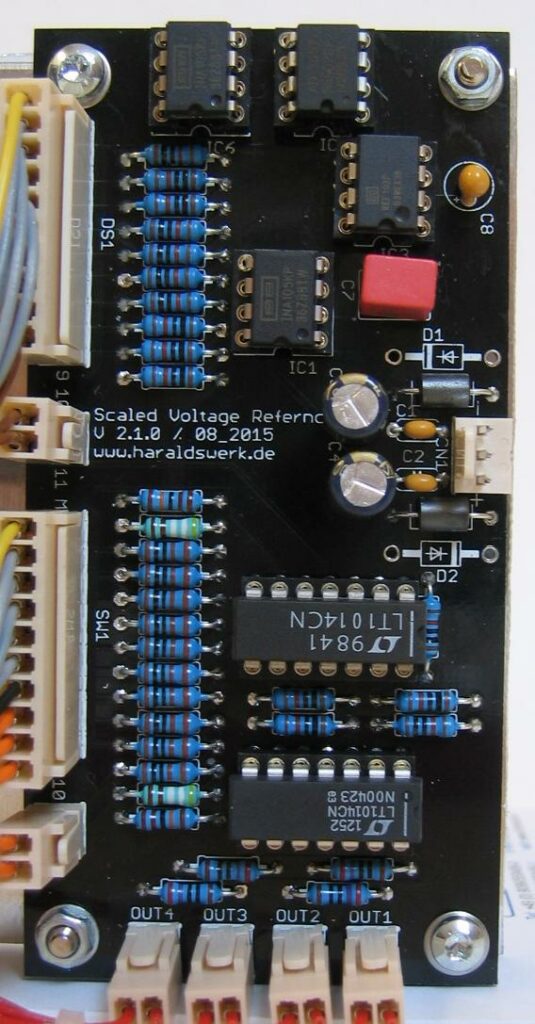

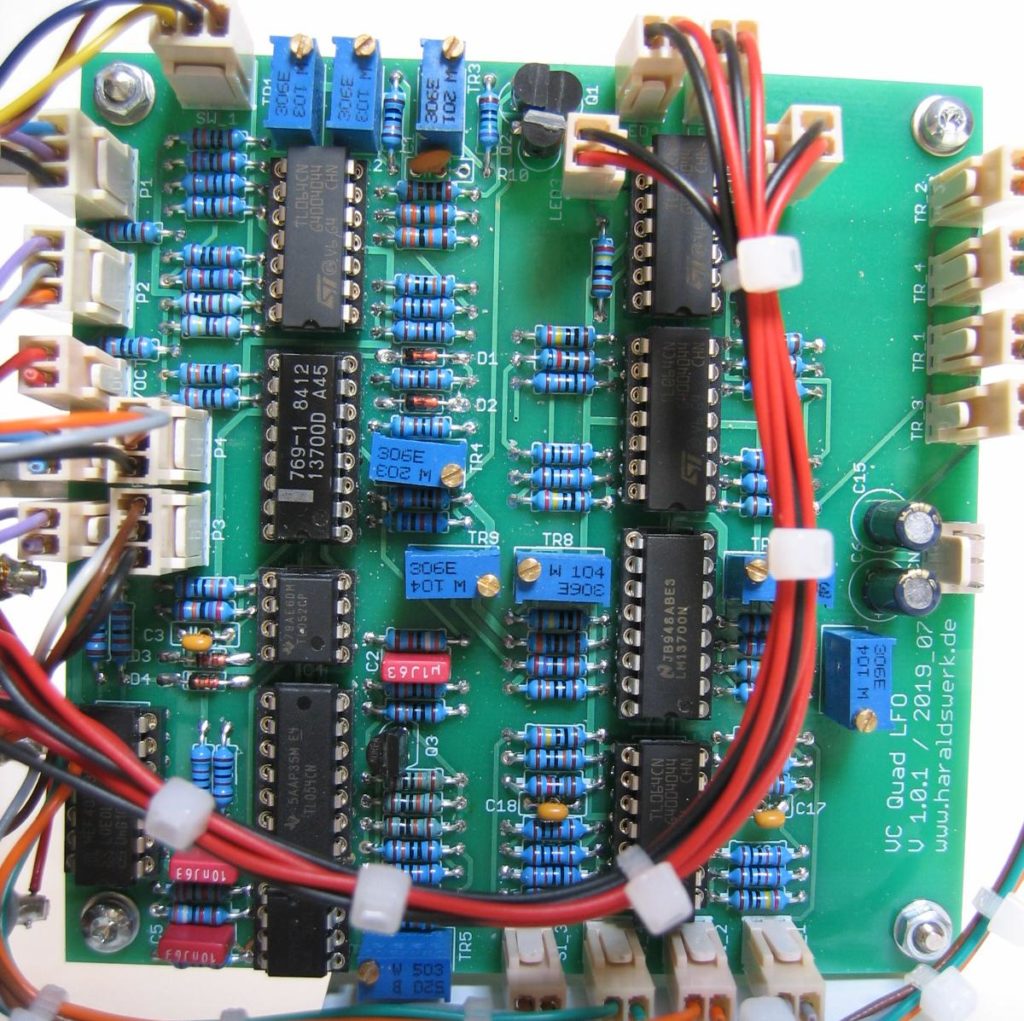

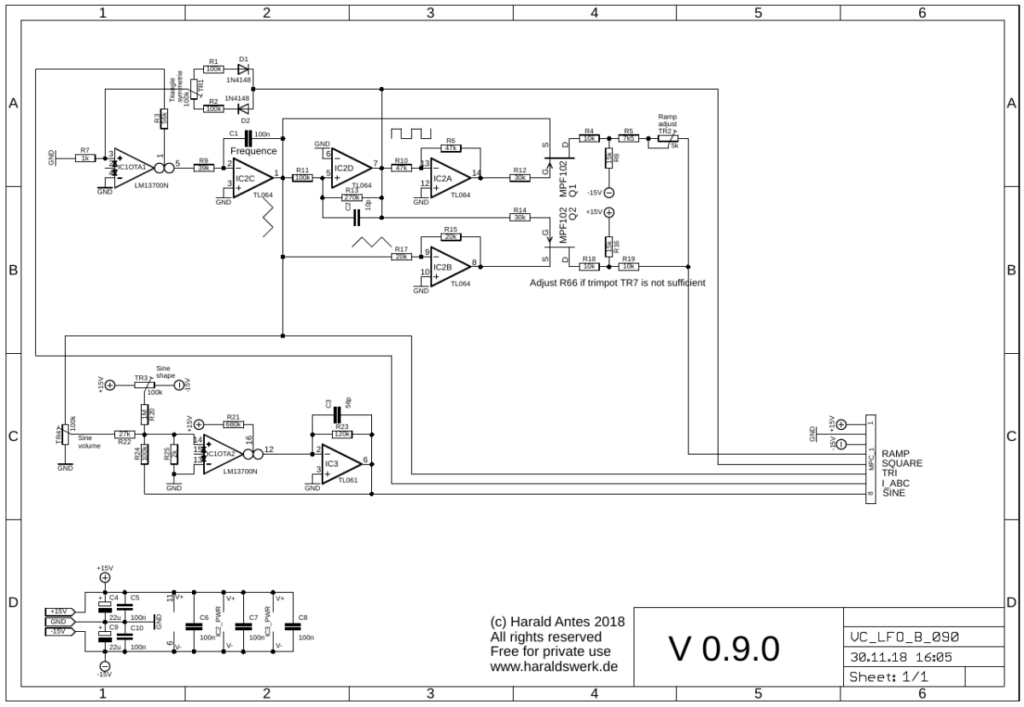

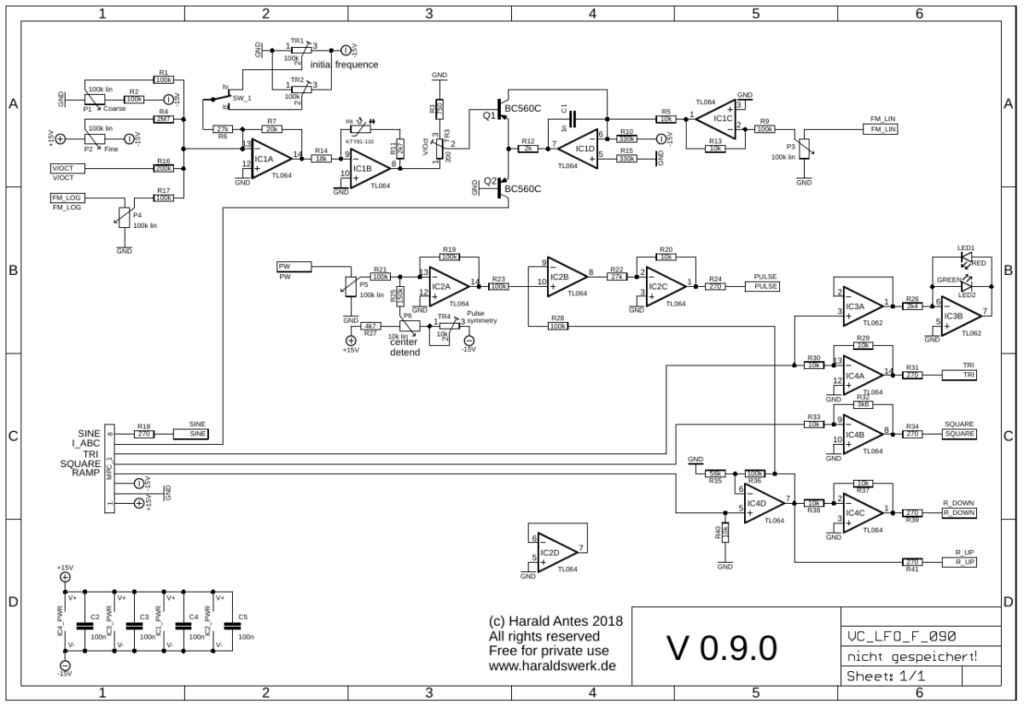

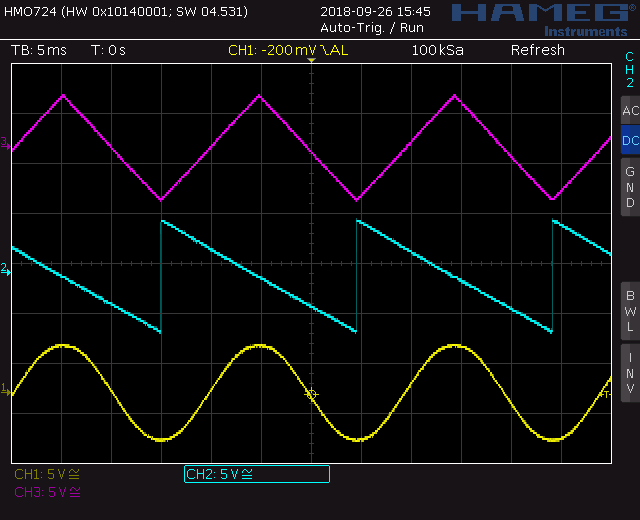

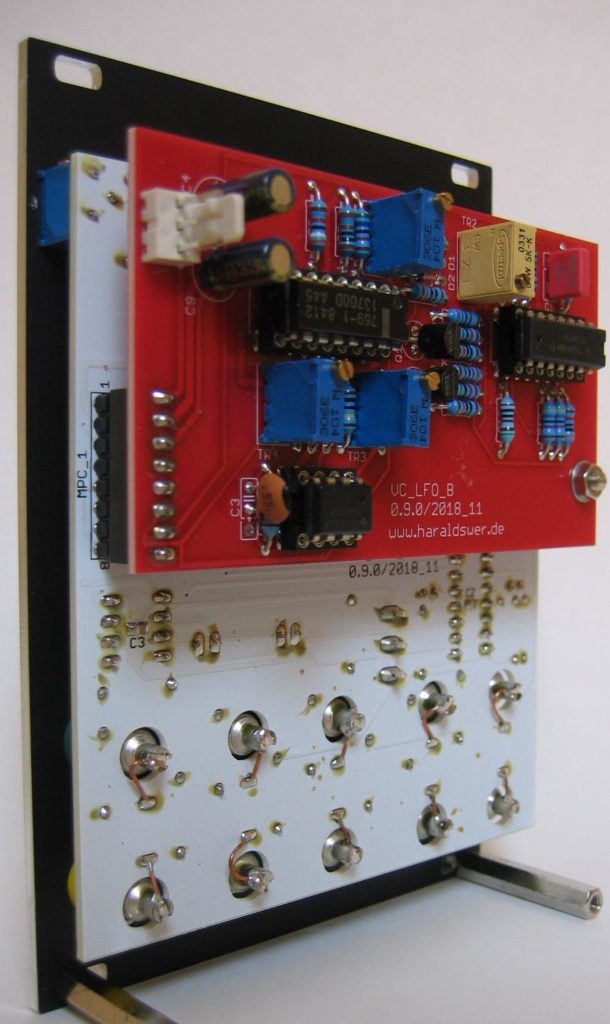

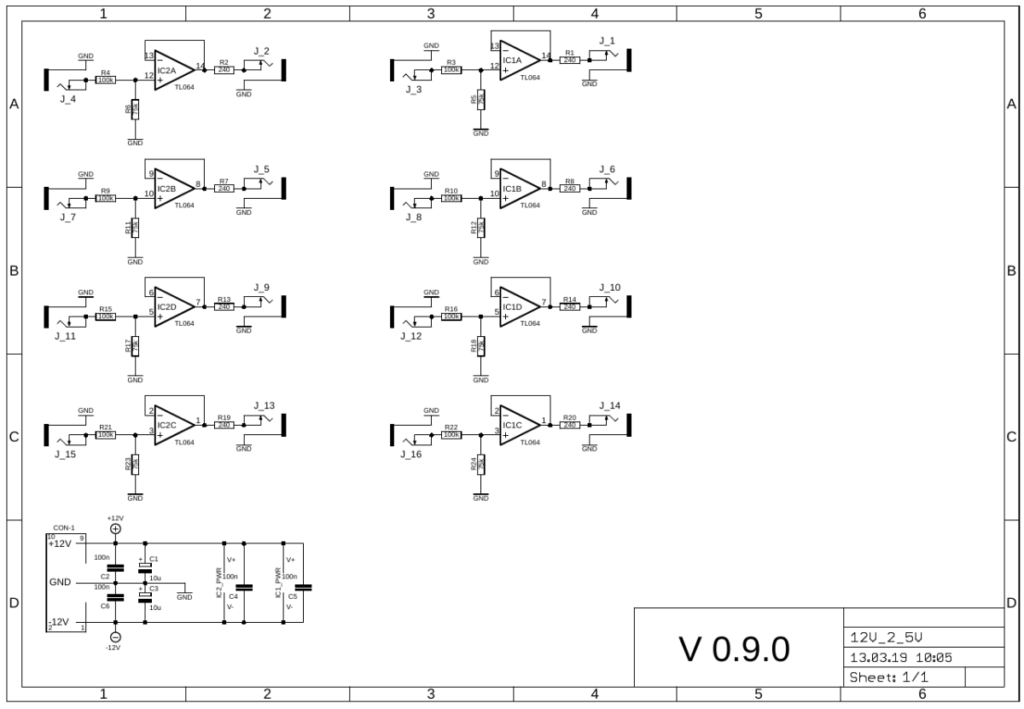

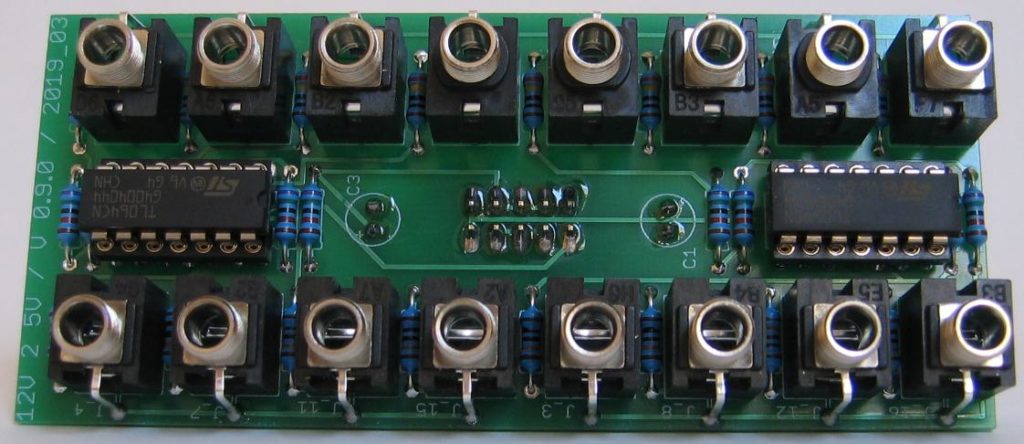

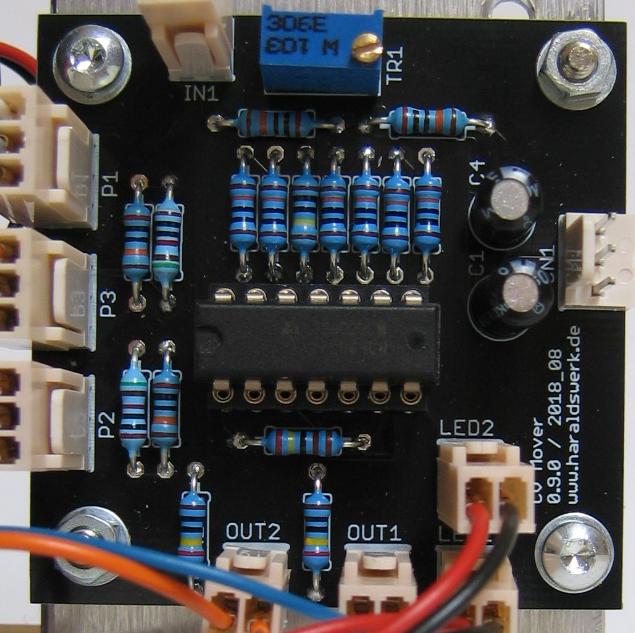

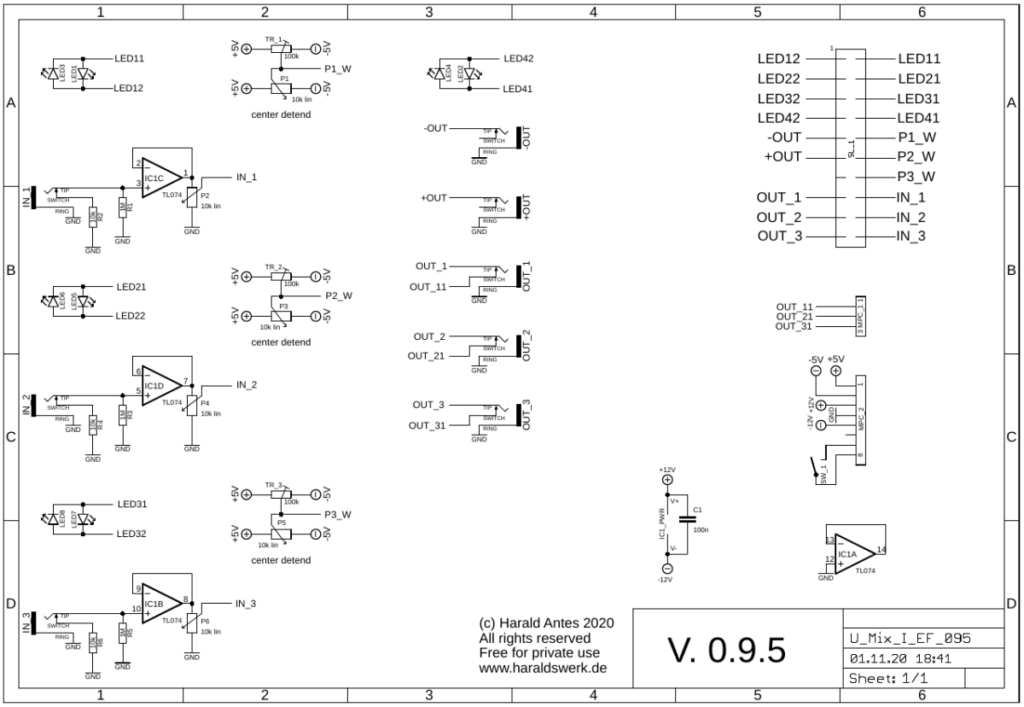

Control board: Straight forward design. The mixer is completely DC coupled. So you can use it for CV mixing as well as audio mixing. IC1B,C,D buffers the three inputs and and keeps the input impedance constant. P2, P4, P6 sets the amplification from zero to 2X. P1, P3, P5 sets the offset voltage. The LED indicates the offset and signal level.

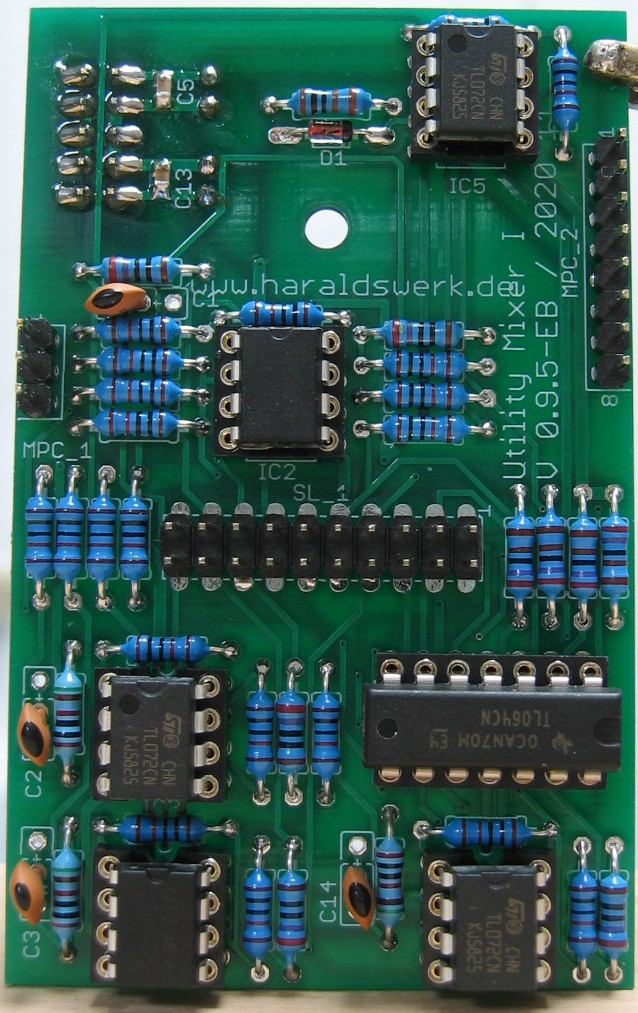

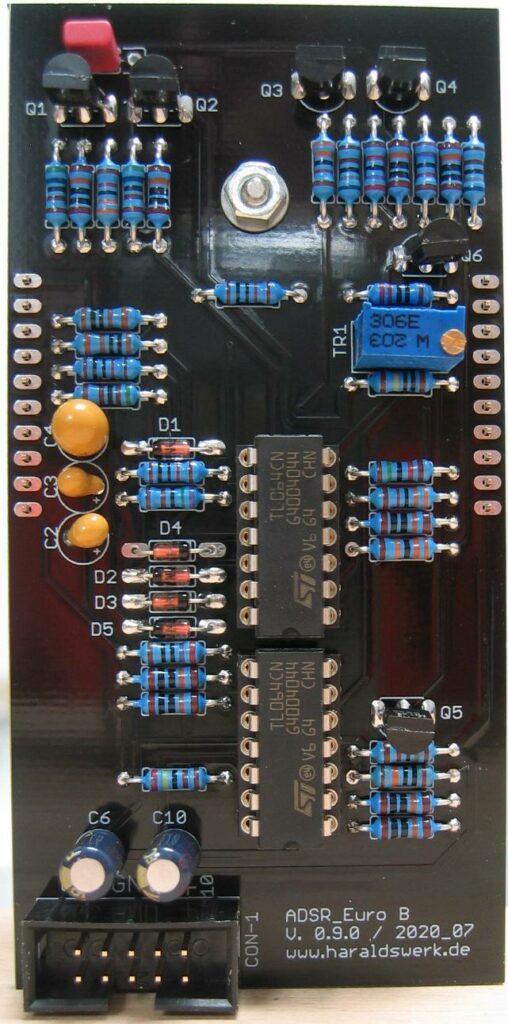

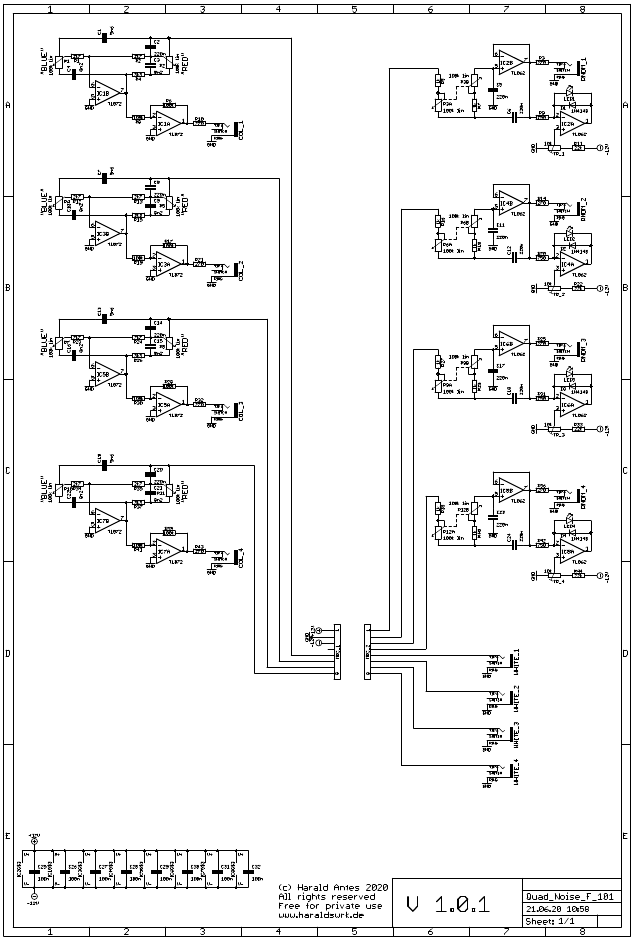

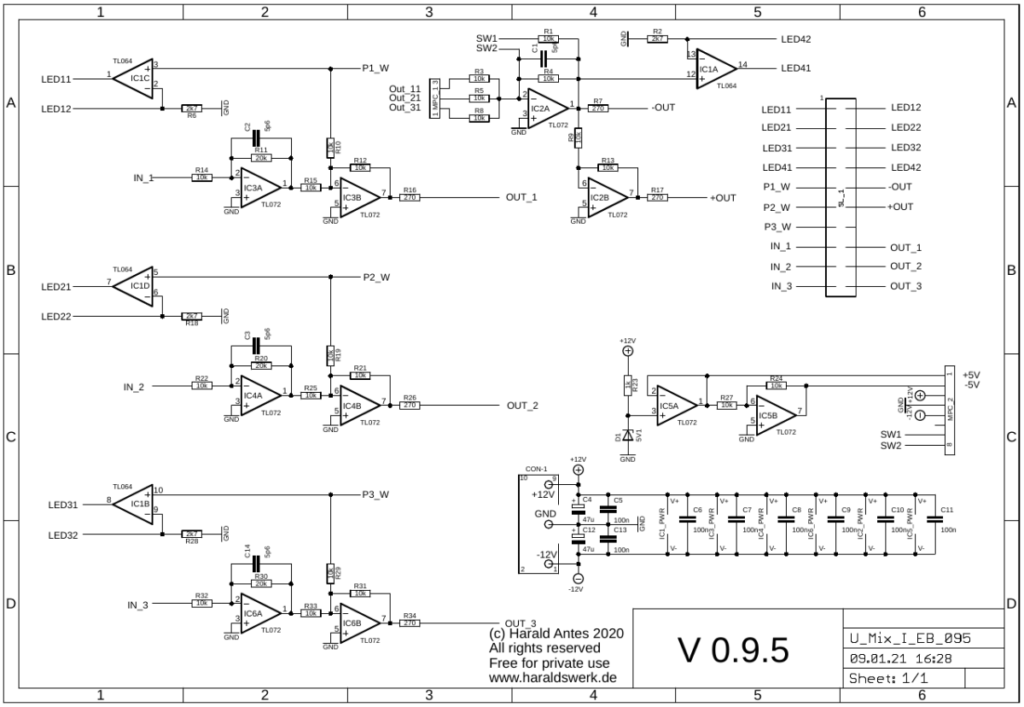

Main board: IC3B, IC4B, IC6B adds the offset voltage and the signal. IC1C, IC1D, IC1B, IC1B drive the low current LED. IC2A sums the signals and drives the negative output. IC2B drives the positive output.